Basement framing is a critical project for any homeowner looking to transform an unfinished space into a functional, inviting area. Whether you’re dreaming of a cozy lounge, a home office, or a playroom, framing is the essential first step that sets the foundation for all your design aspirations. Key benefits include improved insulation, an increase in home value, and versatile space utilization.

When framing a basement, pay attention to:

I’m Ryan Norman, founder of Norman Builders, where we’ve been crafting homes with precision and passion since 2007. With my background in basement framing, we can help make your vision a reality while ensuring structural integrity and quality.

Glossary for basement framing:

– how to finish a basement

– basement insulation

– do you need a permit to finish a basement

Before you dive into framing your basement, preparation is key. This involves gathering safety gear, assembling the right tools, and measuring your space accurately. Let’s break it down step-by-step.

Safety should always come first. When working on basement framing, ensure you’re equipped with the necessary protective gear:

Having the right tools on hand will make the job more efficient and accurate. Here’s a list of essential tools for framing your basement:

Accurate measurements are crucial to avoid mistakes that can be costly in both time and materials. Start by:

Taking these preparatory steps seriously will set the stage for a smooth and successful basement framing project. Once you’re geared up, equipped with the right tools, and have your space carefully measured, you’re ready to move on to the next phase: choosing the right materials for your basement framing.

Selecting the right materials is crucial for a successful basement framing project. The materials you choose will impact the durability, safety, and longevity of your walls. Let’s explore the key materials you’ll need: dimensional lumber, pressure-treated lumber, and fire blocking materials.

Dimensional lumber is the backbone of any framing project. It refers to wood that is cut to standardized width and depth, making it ideal for constructing the framework of your walls.

For areas where wood will come into contact with concrete, pressure-treated lumber is a must. This type of wood is treated with chemicals to resist moisture, rot, and insects.

Fire safety is a critical consideration in basement framing. Fire blocking materials help prevent the spread of fire within wall cavities.

Choosing the right materials is foundational to a successful basement framing project. With the right dimensional lumber, pressure-treated wood, and fire blocking materials, you’re well on your way to building a safe and durable basement framework. Next, we’ll dive into the detailed steps for framing your basement walls.

Framing your basement walls is a rewarding project that improves your home’s living space. Let’s break it down step by step, so you can tackle it with confidence.

Rotary Laser and Chalk Lines

Start by establishing a precise layout using a rotary laser. This tool helps you create a straight and level line around the perimeter of your basement. Mark these lines with a chalk line to guide the placement of your wall plates.

Measuring Tape

Use a measuring tape to mark the locations for your studs on the top and bottom plates. Standard spacing is 16 inches on center, but check your local building codes for specific requirements.

Pressure-Treated Wood

The bottom plate should be made of pressure-treated wood. This protects against moisture from the concrete floor.

Powder-Actuated Tool

Secure the bottom plate to the concrete using a powder-actuated tool. This tool drives nails into the concrete, ensuring a firm attachment.

Stud Placement and Top and Bottom Plates

With your bottom plate in place, it’s time to assemble the wall frame. Position each stud at the marked locations on the bottom plate and attach the top plate.

Plumb Lines and Leveling

Before securing the frame to the joists, ensure the wall is plumb. Use plumb lines and a level to check that the wall is perfectly vertical.

Securing to Joists

Finally, secure the top plate to the ceiling joists. This anchors the wall and provides additional stability.

By following these steps, you’ll have a solid and well-framed basement wall ready for the next phases of your renovation. Next up, we’ll explore some advanced tips for tackling common challenges in basement framing.

Framing a basement is more than just putting up walls. It involves addressing fire safety, dealing with existing obstacles, and ensuring proper insulation and moisture control. Let’s explore these advanced tips to help you achieve a professional finish.

Fire blocking is crucial for preventing the spread of fire through hidden spaces in the framing. It’s not just a safety measure; it’s a code requirement in many areas.

Pro Tip: Always check your local building codes to ensure compliance with fire blocking requirements.

Basements often come with existing structures like ductwork, plumbing, and electrical panels that can complicate framing.

Expert Advice: Plan your layout carefully to minimize the number of obstacles you need to frame around.

Proper insulation and moisture control are vital for a comfortable and dry basement environment.

Insider Tip: Tape all seams of the foam board with construction tape to create a continuous barrier against moisture and air infiltration.

By incorporating these advanced techniques, you’ll not only meet building codes but also create a safer, more efficient, and comfortable basement space.

In the next section, we’ll address some frequently asked questions about basement framing to further improve your understanding of the process.

When it comes to basement framing, choosing the right materials is crucial for durability and safety. Pressure-treated lumber is often the best choice for the bottom plate because it is resistant to moisture and decay, which is common in basements. For the rest of the wall framing, dimensional lumber is typically used. It’s strong, easy to work with, and readily available.

Did You Know? Using pressure-treated wood helps prevent rot and mold, making it ideal for basements that may experience damp conditions.

Ensuring your framing is level and secure is key to a successful project. Start by using a rotary laser or chalk lines to mark out straight and level lines on the floor and ceiling. When installing the bottom plate, use a powder-actuated tool to securely attach it to the concrete floor. This ensures a solid foundation for the walls.

To make sure the walls are plumb, use a level and adjust as necessary before securing the top plate to the ceiling joists. Plumb lines can help in checking vertical alignment, ensuring your walls are perfectly upright.

Expert Tip: Double-check all measurements before cutting and securing materials to avoid costly mistakes.

Building codes for basement framing vary by location, but there are common requirements you should be aware of. Fire blocking is essential and often mandated by code to prevent flames from spreading through wall cavities. Additionally, ensure that there is adequate insulation to meet energy efficiency standards, and that vapor barriers are installed to manage moisture.

Important Note: Always consult your local building department to verify specific code requirements in your area. Permits may be needed, and inspections might be required at different stages of the framing process.

Understanding these FAQs can help you steer the complexities of basement framing with confidence. In the next section, we’ll wrap up the guide and highlight the importance of precision in every step of the process.

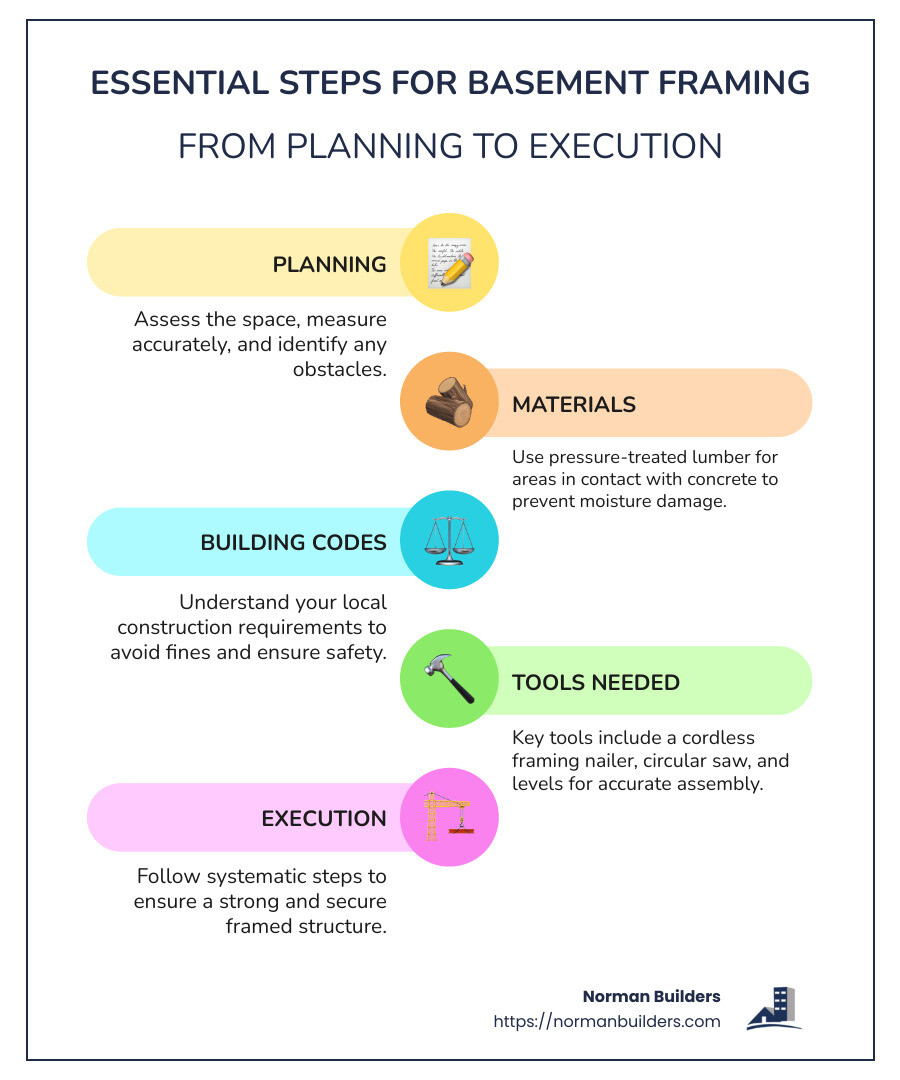

Framing your basement is a rewarding DIY project that can transform your home’s unused space into a functional area. Throughout this guide, we’ve covered essential steps—from planning and measuring to choosing the right materials and installing the frame. Each step is crucial for achieving a professional finish and ensuring the structural integrity of your new walls.

Precision is Key: Accurate measurements and careful installation are vital. They ensure your walls are straight, secure, and compliant with local building codes. This attention to detail not only guarantees safety but also improves the overall value of your home. Taking the time to do it right the first time can save you from costly mistakes and repairs later on.

If you’re ever in doubt or need professional assistance, Norman Builders is here to help. With years of experience in basement framing and remodeling, we provide top-tier craftsmanship and personalized service. We understand the unique challenges of basement projects and are committed to turning your vision into reality.

Whether you’re creating a cozy family room or a sophisticated home office, framing your basement is a critical step that lays the foundation for your dream space. If you prefer to leave it to the experts, contact Norman Builders for a seamless and stress-free experience.

By following this guide, you can confidently start on your basement framing project, knowing you’re equipped with the knowledge to succeed. Enjoy the change and the added value it brings to your home!

We specialize in high-quality home construction and remodeling services, delivering exceptional craftsmanship tailored to meet your vision and needs. Whether you’re planning a renovation, new construction, or a custom remodel, our experienced team is committed to exceeding expectations with precision, attention to detail, and reliable service.

Our service area includes the Merrimack Valley, North Shore, Seacoast, and Southern NH Areas. We take pride in the quality of our workmanship and our prompt professionalism.

Contact us today to bring your project to life!